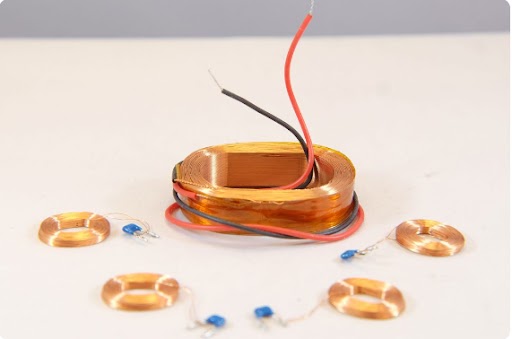

The ever-changing state of coil technology is a key factor propelling developments in many different businesses within the realm of electromechanical engineering. When compared to conventional wound coils, self-supported coils provide far better performance and dependability, making them a major advancement among these advancements. The shape and function of these specialist coils may be maintained without an external framework, thanks to their careful design. This leads to a decrease in material costs and an improvement in operating efficiency.

A self-supported coil can keep its shape and dimensions even when not attached to anything else. Coils with this one-of-a-kind quality are the result of meticulous engineering and the use of premium materials designed to endure operational mechanical loads and temperature fluctuations. Applications, where space and weight are essential issues, are well-suited to self-supported coils because of their design flexibility, which permits more compact and efficient arrangements.

Industries that need tailored solutions greatly benefit from the unique characteristics of self-supported coils. The performance and longevity of custom assemblies with self-supported coils may be fine-tuned to match unique operating needs. These assemblies are used in several applications that demand the utmost accuracy and dependability, such as medical devices and automotive components.

The capacity to function in harsh environments is a major benefit of using high-performance, self-supported coils. These coils are designed to be very efficient and to keep performing well in a variety of temperatures and operating conditions. For mission-critical applications, this feature is essential as it guarantees continuous performance and prolongs the life of the coils.

Industries that use magnetic coils must have a reliable source for high-performance bespoke coils. These vendors are experts in making high-quality coils that can perform above and beyond expectations. They are able to meet the specific demands of their customers by using their extensive knowledge in bespoke coil design and manufacture to provide solutions that are both dependable and highly effective.

Advanced technology and rigorous quality control systems are necessary for the production of High-performance magnetic coils manufacturer. Suppliers specializing in these coils often use cutting-edge methodologies and materials to guarantee that every coil adheres to the utmost benchmarks of quality and performance. The emphasis placed on quality not only serves to improve the dependability of the coils but also plays a significant role in the development of electric-based technologies.

The use of self-supported coils is changing many fields, such as healthcare, automobiles, aircraft, and green energy. In sustainable energy, these coils are put in motors and engines to make them more energy efficient and less harmful to the environment. Their work in the automobile industry helps make electric cars lighter and more fuel-efficient. In aerospace, these coils help make things lighter and more reliable, and in healthcare, they are essential for making high-precision medical devices.

The future holds boundless possibilities for the development of coil technology. More advanced designs, the result of continuing R&D, may open up new applications and enhance current systems. Improved materials and cutting-edge production methods should take self-supported coils to a whole new level of performance and dependability.

Improving electromechanical systems via increased efficiency and dependability has never been easier than with the recent developments in self-supported coils. The importance of professional coil manufacturers like qualitycoils.com is rising in response to the rising need for eco-friendly and high-performance solutions. Their dedication to excellence and innovation guarantees that businesses worldwide can depend on cutting-edge coil technology to propel their operations forward.