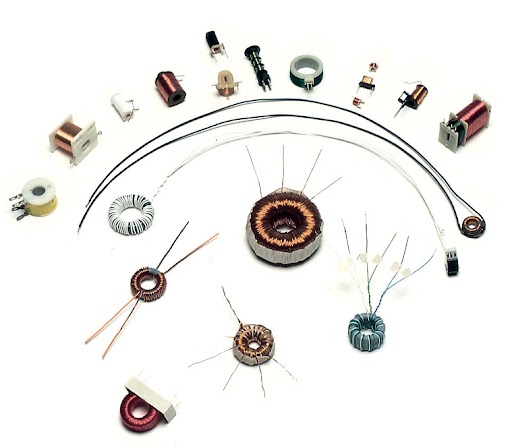

These days, unique and personalized solutions are more important than ever because technology is always changing. Custom coil assemblies are important parts that are used in many fields, such as medicine, the car industry, and others. In addition to meeting the bare minimum requirements, these unique solutions try to push the limits of what is possible, promise peak performance, and give you an edge over other companies.

Electromagnetic induction is the main idea behind custom coil systems. The coils are made of metals like copper or aluminum and are carefully formed into exact shapes so that when an electric current flows through them, magnetic fields are created. The customization part comes into play when these coils are changed to fit the specific needs of different uses. This includes changing their size, shape, and electrical properties.

Custom coil windings hold together these systems. There isn’t a single size that fits all; instead, they are carefully designed to fit the needs of each purpose. Customizing coil windings is what makes these solutions unique, whether it’s a tight winding for a small area or a certain pattern to get a certain magnetic field.

Copper is often used for custom-made coils because it is a good conductor of electricity. Companies that make Custom Wound Copper Coil manufacturers are sought after in fields where dependability and high effectiveness are very important. Precision and quality are very important to companies that make these coils, and they make sure that every coil meets their customers’ strict needs.

Custom electric coil solutions are at the heart of driving progress in many areas. These customized solutions are made to give specific applications the exact performance traits they need. Custom electric coil solutions are the answer to tough problems in a wide range of areas, from medical devices that need precise magnetic fields to car parts that need to work in harsh conditions.

The great thing about handmade coil systems is that they can be changed to fit specific needs. This customization isn’t limited to the coils’ looks; it also includes their electrical qualities, how they handle heat, and how they’re built into the final product. With this level of tailoring, each coil assembly is not just a part but a solution that makes the application run better and more efficiently as a whole.

Making handmade coil systems isn’t just about making things; it takes skill and creativity. To do this, you need to know a lot about electromagnetics, materials science, and the needs of the application. Custom solutions manufacturers often work closely with their clients, using their knowledge to come up with new ideas and create truly unique solutions.

In a world where people want more and more customized solutions, custom coil systems stand out as an important part of driving success and innovation. These systems are special because they can be changed to fit specific needs. This is true for custom coil windings, custom-made copper coils, and custom electric coil solutions. If you want the best quality and accuracy in custom coil systems, qualitycoils.com is the name you can trust. They offer options that are expertly made to meet the highest standards.